Labels

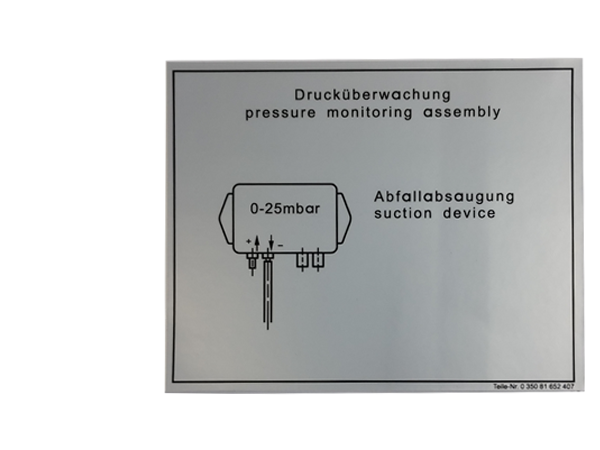

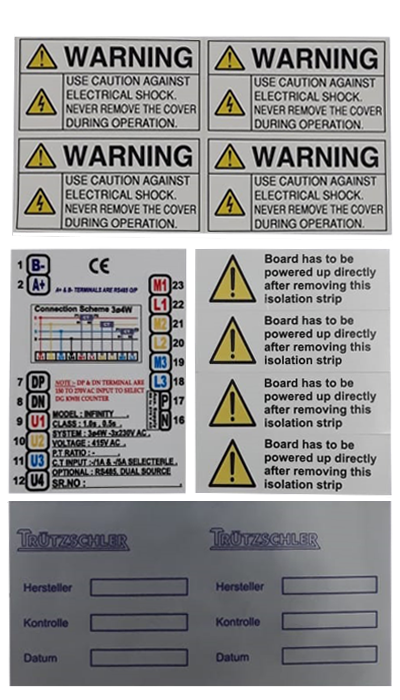

Labels serve instructional, illustrative, and schematic purposes. It can take whatever form or design you like. IntraAction uses 3M or equipment to create medical labeling from Polyester, Polycarbonate, or vinyl. Our in-house CNC cutting equipment can cut any complex shape you can imagine. There are currently in-stock items with Standard labels. It's helpful to label process flow charts and product flow diagrams. The pharmaceutical sector, the chemical industry, and continuous-process manufacturing can all benefit from it.

What makes our product the best?

Application Process for Labels

A product's labelling plays a significant role in its advertising. Having eye-catching packaging that stands out to potential buyers is crucial. It can be utilized with the product's packaging to entice consumers to purchase. Convenience and data transfer are two further functions served by packaging. Instructions for use, storage, recycling, and trashing are printed on or attached to the packaging.

When designing a product, we advise our customers to consider its intended use and context. Consider whether the durable labeling will be used for product id, safety warnings, tracking, expiration dates, asset tracking, or other functions. Consider your label's potential hazards, such as excessive humidity, moisture, dust, and exposure to chemical solvents, corrosive compounds, abrasives, and other potentially damaging elements.

High-Speed Printing & Converting for Labels

In addition to being inconvenient, delivery delays can harm your bottom line. Because of this, IntraAction Electronics works hard to improve efficiency and implement cutting-edge technology to meet your demands for rapid, accurate, flexible, and reasonably priced mass manufacturing.

High-speed digital printing and converting industrial labels are fast, accurate, flexible, and inexpensive. The streamlined design ensures the highest levels of precision and quality while reducing material waste, waiting times, and late delivery.