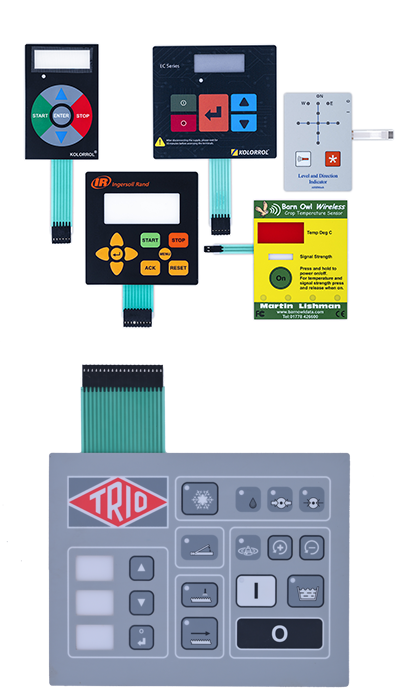

Membrane Switches

Membrane switches, membrane panels, or keypads are small, integrated printed electrical circuits designed to withstand millions of actuations. Pressure is used to open and close the circuit in a membrane switch, which is a printed, electronic circuit. Screen printing techniques commonly print the conductive inks that comprise the membrane switch circuitry. User interfaces include backlit membrane switches, display-based touch screens, and mechanical switches like push buttons, toggles, rockers, and sliders.

Membrane Switches

Applications of Membrane Switches

Consumer appliances like coffee makers, ovens, thermostats, televisions, audio/video systems, and some lighting all use backlit membrane switches. The membrane switch is a common component in electronic gaming gadgets. Membrane switches are essential to operate vending machines, automated teller machines, and self-checkout kiosks. Membrane switches remotely regulate hazardous operations, such as those performed by large construction cranes, mining and excavation equipment, and metal processing plants.

Membrane switch keypads operate various farm machines, canning and bottling lines, conveyor systems, inventory tracking devices, cash registers, and ovens. For reliable operation and a good tactile feel with the low tactile force required to operate the keypads, Membrane Switches manufacturer IntraAction Electronics must incorporate excellent stainless-steel domes into the design of the membrane switches.

Characteristics of a Membrane Keyboard

Electrical contacts on the various membranes of a switch come together to perform their essential function. Because the electrical connection remains incomplete until the switch is triggered, backlit membrane switches are always in the "off" position until they are physically flipped. Most membrane switches are activated by applying pressure to the device, which brings the contacts of the various membranes together.

At IntraAction Electronics, we are a top notch Membrane Switches manufacturer that meets the needs of our customers. Our keypad is manufactured by trained professionals using premium components and following all applicable standards. This keypad is also tried in different ways to look for flaws and ensure it is of good quality. Several variations of this keypad are available to serve our customers better.