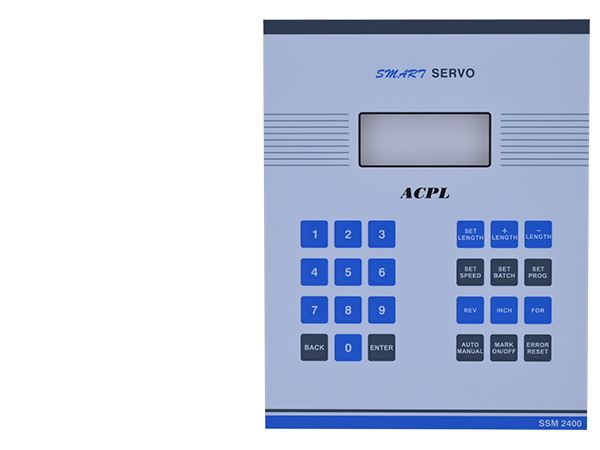

PCB-Based Membrane Keyboard

A PCB membrane keyboard is made up of keys, a front panel, text, markings, a logo, and see-through windows. The graphic overlay's layout can also convey how the product's features and the original colours work together. Intelligent electronics measuring instruments, medical instruments, computer control, computer numerically controlled (CNC) machine tools, terminal communication equipment, and various industrial and household appliance products (including microwave ovens, photocopiers, refrigerators, electronic game machines, electric fans, washing machines, etc.) all make use of membrane keyboard PCB.

PCB-Based Membrane Keyboard

Areas of Use for Membrane Switches

Lightweight, all-in-one Printed Electronics & Bio Sensors designed to withstand millions of actions—that’s what Backlit Membrane Switches/Keypads, also known as membrane panels or keypads—is. Membrane switches are superior to bulky, inflexible alternatives because they are built from layers of thin, flexible, and conductive materials. There are at least five layers in every membrane switch.

Each layer of these switches has a specific purpose, and they are easily put together using pressure-sensitive adhesives or heat-sealing films. The graphic presentation, adhesive layer, PCB layer, circuit layer, graphic adhesive, adhesive separator, second circuit layer, and metal domes comprise the bulk of this switch's important layers. The following discussion will go over each layer as well as the function it serves.

Parameters for a PCB-Based Membrane Keyboard

In this industry, we pcb membrane keyboard manufacturers have made a reputation for ourselves by consistently delivering high-quality products, and our membrane keyboard pcb is no exception. This item utilizes premium quality components and modular machinery following established business norms. Our experts conduct rigorous testing over a wide range of criteria to ensure the quality of the final product. Our devoted clientele can purchase this item from us at a price that won't break the bank.

We the best flexible keypad manufacturer provides PCB Membrane Keypad to fulfil our client's requirements. Our skilled personnel use high-quality raw materials and follow all relevant industry requirements in producing the keypad we offer. Moreover, this keypad is tested in various ways to check for defects and ensure quality. We provide this keypad in several configurations to meet our customers' needs.